Guide to buying a shipping container

Nov 11, 2013 16:42:49 GMT 10

SA Hunter, Jason, and 4 more like this

Post by Ausprep on Nov 11, 2013 16:42:49 GMT 10

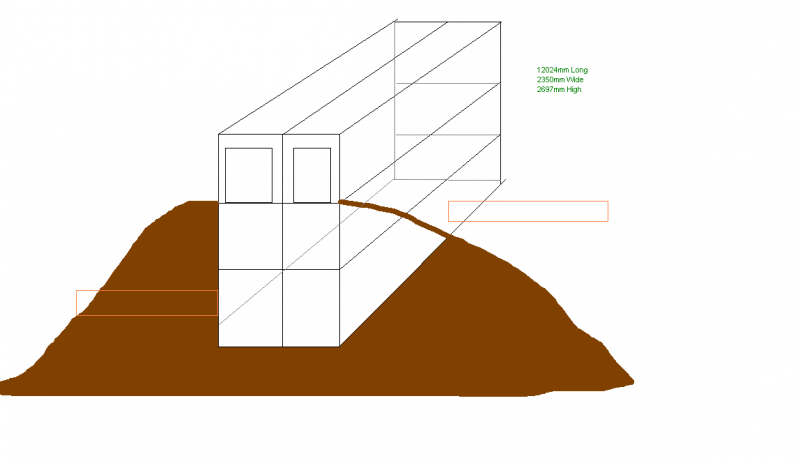

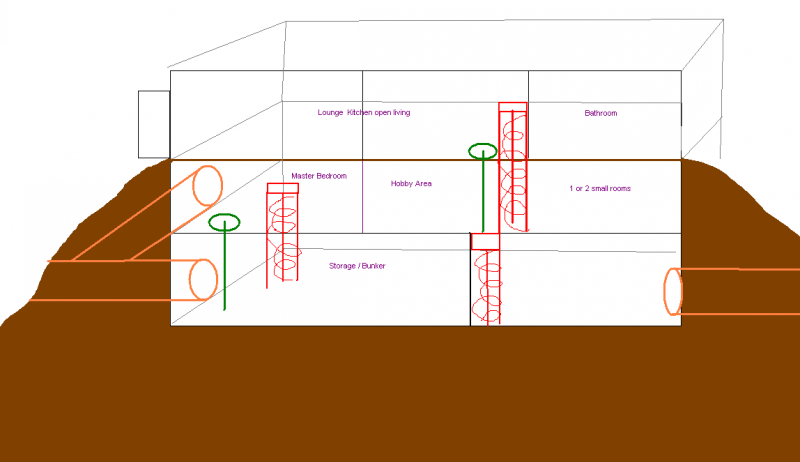

I know i want one. My idea isn't to bury them deep down, but more a partially buried, multiple container, container home.

Shipping containers can be a great resource for a prepper, and it’s important to have a good understanding of all aspects of shipping containers, both direct and indirect, before you start your project.

Local Regulations and Zoning

Containers Available in Your Area

Materials and Design

Delivery

Maintenance and Care

Local Regulations and Zoning

Depending on where you live local zoning and regulations can kill any type of building project before it starts, and container structures are no different. The key thing to keep in mind when you’re doing your research and asking questions is “permanent foundation”. In most areas anything that sits on a permanent foundation, ie: is attached securely to the ground, requires a building permit and is subject to all the normal codes and inspections that go with it. Factor in a shipping container being a core component and you run the risk of having a confused civil servant on your hands. If your container project isn’t physically attached to the ground you may not need a permit.

Shipping Containers in Your Area

Once you’ve cleared your project with regards to local regulations, you’ll want to research what types of containers are available in your area. 20’, 40’ and 40’ high cube containers are the most common, and in some areas you can find 20’ high cubes and 45’ high cubes. Having a shipping container delivered a long distance can get expensive quickly, and if you start to design your project prior to researching inventory you may find that the containers you want either aren’t in your area, or your project cost is incredibly high due to delivery charges.

Materials and Design

This is where your container project starts to get really interesting. By now you’ve probably got a good idea of what you want it to look like and the functions it will serve: fallout shelter, vault, storage facility, or even a hydroponic farm. Without exploring every option, we’ve listed out a few core features below that are common components of nearly every project.

Doors: Man doors and roll up doors are both common to install. Man doors can be easily secured and easily sourced. Roll up doors are great for moving larger equipment in/out of the container, however they are less secure.

Insulation: Spray foam, rigid ply, and ceramic paint insulation are three options that we recommend. We’d stick with these three as they have the least capacity to hold moisture, and the last thing you want pressed up against the steel walls of a shipping container is damp insulation.

If your project will remain air tight, depending on where it’s located will be located you may need to consider how to manage moisture and condensation. Most containers come with small breather vents already installed, but they may not be able to keep up with large night/day temperature shifts that can produce condensation.

Shelving: Shelving and storage is a big factor in any container project, especially one that may be stocked with a large non-perishable food supply. You’ll want to create shelving that is strong and durable. Steel shelving that bolts to, or hangs on, the container walls is optimal. Wooden shelving takes up more space, supports less weight, and could catch on fire.

Electricity: Tapping into the power grid is probably out of the question for many reasons (you’ll be reliant on a third party, it puts you on the radar, and it’s an additional monthly cost). Solar panels can be attached to the roof of the container for daytime collection, or you can purchase an external generator. If you do purchase an external generator you’ll need to factor in a fuel supply.

Shipping Container Delivery

Before the container is delivery the foundation should be in place, unless you have equipment onsite that can move the container onto its foundation, or lift the container while you build underneath of it.

When arranging the delivery of your container, be sure to inform the driver of the specific details of the location. The roads should be clear and dry, and the truck will need ample room to move around and drop the container on the ground.

Maintenance and Care

Shipping containers, by design, require very little maintenance. Once or twice a year, we recommend spring and fall, it’s good to inspect the inside and outside of the container to check for any rust, corrosion, or flaking paint. If you happen to find any you’ll want to clean the area with steel wool or a wire brush and repaint the area. If the original doors are still in use you may want to make sure they’re adequately greased and the doors are square.

Shipping containers can be a great resource for a prepper, and it’s important to have a good understanding of all aspects of shipping containers, both direct and indirect, before you start your project.

Local Regulations and Zoning

Containers Available in Your Area

Materials and Design

Delivery

Maintenance and Care

Local Regulations and Zoning

Depending on where you live local zoning and regulations can kill any type of building project before it starts, and container structures are no different. The key thing to keep in mind when you’re doing your research and asking questions is “permanent foundation”. In most areas anything that sits on a permanent foundation, ie: is attached securely to the ground, requires a building permit and is subject to all the normal codes and inspections that go with it. Factor in a shipping container being a core component and you run the risk of having a confused civil servant on your hands. If your container project isn’t physically attached to the ground you may not need a permit.

Shipping Containers in Your Area

Once you’ve cleared your project with regards to local regulations, you’ll want to research what types of containers are available in your area. 20’, 40’ and 40’ high cube containers are the most common, and in some areas you can find 20’ high cubes and 45’ high cubes. Having a shipping container delivered a long distance can get expensive quickly, and if you start to design your project prior to researching inventory you may find that the containers you want either aren’t in your area, or your project cost is incredibly high due to delivery charges.

Materials and Design

This is where your container project starts to get really interesting. By now you’ve probably got a good idea of what you want it to look like and the functions it will serve: fallout shelter, vault, storage facility, or even a hydroponic farm. Without exploring every option, we’ve listed out a few core features below that are common components of nearly every project.

Doors: Man doors and roll up doors are both common to install. Man doors can be easily secured and easily sourced. Roll up doors are great for moving larger equipment in/out of the container, however they are less secure.

Insulation: Spray foam, rigid ply, and ceramic paint insulation are three options that we recommend. We’d stick with these three as they have the least capacity to hold moisture, and the last thing you want pressed up against the steel walls of a shipping container is damp insulation.

If your project will remain air tight, depending on where it’s located will be located you may need to consider how to manage moisture and condensation. Most containers come with small breather vents already installed, but they may not be able to keep up with large night/day temperature shifts that can produce condensation.

Shelving: Shelving and storage is a big factor in any container project, especially one that may be stocked with a large non-perishable food supply. You’ll want to create shelving that is strong and durable. Steel shelving that bolts to, or hangs on, the container walls is optimal. Wooden shelving takes up more space, supports less weight, and could catch on fire.

Electricity: Tapping into the power grid is probably out of the question for many reasons (you’ll be reliant on a third party, it puts you on the radar, and it’s an additional monthly cost). Solar panels can be attached to the roof of the container for daytime collection, or you can purchase an external generator. If you do purchase an external generator you’ll need to factor in a fuel supply.

Shipping Container Delivery

Before the container is delivery the foundation should be in place, unless you have equipment onsite that can move the container onto its foundation, or lift the container while you build underneath of it.

When arranging the delivery of your container, be sure to inform the driver of the specific details of the location. The roads should be clear and dry, and the truck will need ample room to move around and drop the container on the ground.

Maintenance and Care

Shipping containers, by design, require very little maintenance. Once or twice a year, we recommend spring and fall, it’s good to inspect the inside and outside of the container to check for any rust, corrosion, or flaking paint. If you happen to find any you’ll want to clean the area with steel wool or a wire brush and repaint the area. If the original doors are still in use you may want to make sure they’re adequately greased and the doors are square.

.

.

) and lead to the bunker - this is where I'd bring my family during a fire/emergency/whatever. The other half would be my preserves and other stores.

) and lead to the bunker - this is where I'd bring my family during a fire/emergency/whatever. The other half would be my preserves and other stores.

I'd like some info on how you would go about reinforcing and insulating these even if they weren't going to be buried.

I'd like some info on how you would go about reinforcing and insulating these even if they weren't going to be buried.